Q&A

Design problems of medical equipment components2024-05-20

With the rapid development of science and technology and the continuous progress of the healthcare industry, the design of medical equipment components is facing new challenges. Based on the Biomomentum Canada multifunctional tissue material Biomechanical properties, potential distribution test analysis and characterization system, we know that the use of specified materials, the pursuit of structural optimization and improved operational performance are important goals in the design of medical device components.

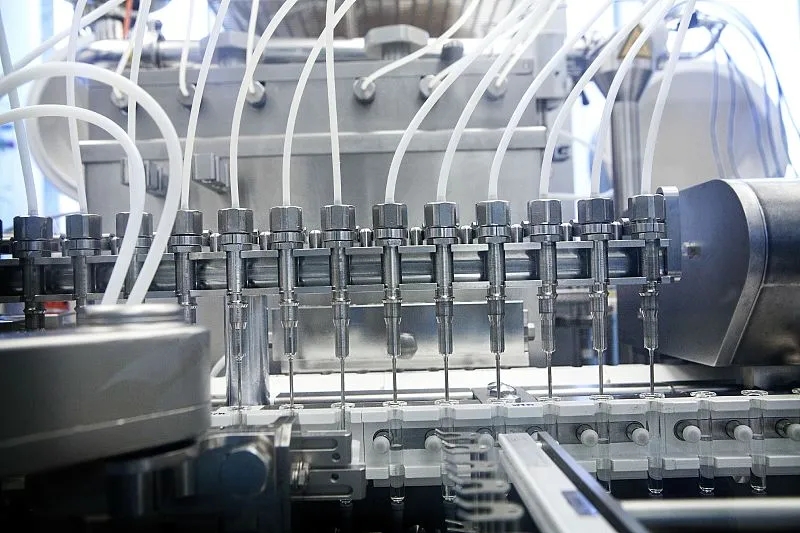

First of all, when conducting product development, one thing to consider is the choice of materials. Typical are stainless steel, titanium alloy, plastic and aluminum alloy, etc., these materials have different characteristics and scope of application. For example, stainless steel has high strength and corrosion resistance, which is suitable for the manufacture of medical devices. Titanium alloy has high strength and corrosion resistance, which is suitable for the internal structure of manufacturing medical devices; Plastic has good plasticity and corrosion resistance, and is suitable for manufacturing the shell and internal structure of medical devices; Aluminum alloy has good plasticity and corrosion resistance, and is suitable for manufacturing the shell and internal structure of medical devices.

Secondly, when designing medical device components, another important factor to consider is the optimization of the structure. For example, the shell design of medical equipment needs to consider ergonomics, simplicity and easy cleaning and maintenance, and take into account the particularity of the medical environment. In addition, the internal structural design of medical devices needs to take into account the operational performance and service life of the device, for example, the use of environmentally friendly materials and removable structures, as well as the optimization of production processes.

Finally, the design of medical equipment components also needs to take into account the operational performance and service life of the equipment. For example, the housing of medical equipment needs to have good corrosion resistance and wear resistance to ensure the service life of the equipment; The internal structure of the medical equipment needs to have good operational performance and stability to ensure the use of the equipment.

In general, the design of medical equipment components needs to take into account the selection of materials, the optimization of structure and the improvement of operational performance. Only through continuous research and development and improvement can we design more excellent medical equipment parts and make greater contributions to the development of the healthcare industry.