Q&A

Environmental protection measures for auto parts processing2024-05-20

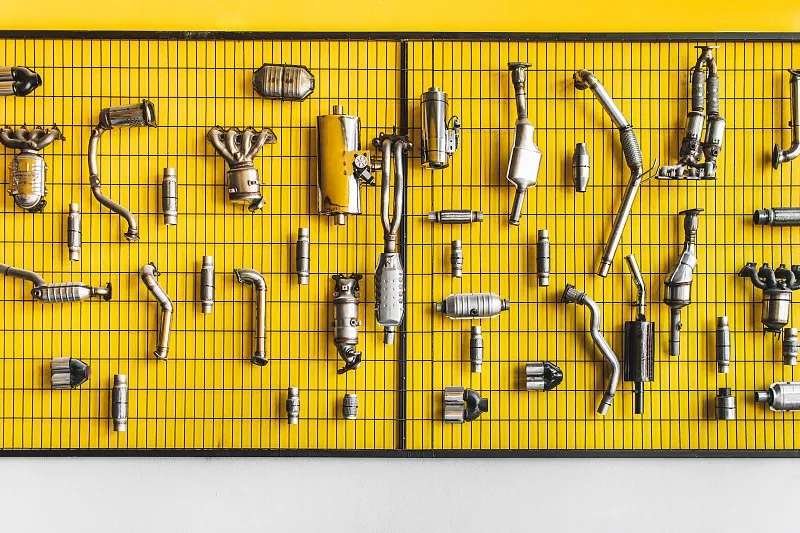

With the rapid development of the economy and the improvement of living standards, consumers' demand for cars is becoming more and more intense. The automobile production process involves a large number of parts processing, and these processing processes will produce a lot of waste gas, waste water, solid waste and noise and other pollutants. In order to protect the environment and reduce the damage to human and natural resources, auto parts processing enterprises need to take a series of environmental protection measures.

First of all, auto parts processing enterprises need to use energy saving and emission reduction technologies, such as low temperature catalytic oxidation method, adsorption adsorption recovery method, photocatalytic oxidation method, etc., to reduce exhaust emissions. For example, RTO regenerative oxidation furnace equipment is a simple operation, easy maintenance, low operating costs, VOCs purification efficiency of up to 99% of the equipment, suitable for painting waste gas, printing waste gas, chemical waste gas, paint waste gas and so on.

Secondly, auto parts processing enterprises need to strengthen wastewater treatment and adopt advanced wastewater treatment technology, such as biological treatment technology, to reduce wastewater discharge. At the same time, enterprises also need to strengthen the monitoring and management of wastewater to ensure that wastewater treatment meets national standards.

In addition, auto parts processing enterprises also need to strengthen the management of solid waste, the use of classified recycling, resource utilization and other ways to reduce the production and emission of solid waste. At the same time, enterprises also need to strengthen the monitoring and management of solid waste to ensure that solid waste treatment meets national standards.

Finally, auto parts processing enterprises need to strengthen noise control, the use of advanced noise control technology, such as sound insulation, sound absorption, noise reduction, etc., in order to reduce the generation and emission of noise. At the same time, enterprises also need to strengthen the monitoring and management of noise to ensure that noise control meets national standards.

In short, auto parts processing enterprises need to take a series of environmental protection measures to protect the environment and reduce the damage to human and natural resources. These measures include adopting energy-saving and emission-reduction technologies, strengthening wastewater treatment, strengthening solid waste management and strengthening noise control. Only in this way can we achieve sustainable development and create a better future for mankind.